Biozyme - Effervescent biological activator - Zep Industries

Effervescent biological powder activator based on cultures of microorganisms, enzymes and nutrients.

Effervescence allows for better diffusion and activation of the product.

Contributes to the proper functioning of grease trap evacuation systems. Cleans septic tanks , manholes, cesspools and delays pumping .

Volume discounts

| Quantity | You Save | Unit price |

|---|---|---|

| 3 | 3 % | €270.17 |

| 5 | 6 % | €261.81 |

| 12 | 10 % | €250.67 |

Biozyme - Effervescent biological activator - Zep Industries

Effervescent biological powder activator based on cultures of microorganisms, enzymes and nutrients.

Effervescence allows for better diffusion and activation of the product.

Contributes to the proper functioning of grease trap evacuation systems. Cleans septic tanks , manholes, cesspools and delays pumping .

Properties :

- Biological activator in effervescent powder based on cultures of microorganisms, enzymes and nutrients necessary for the awakening of biological activity.

- Effervescence allows for better diffusion and activation of the product.

- Contributes to the proper functioning of grease trap evacuation systems, allows you to space out the cleaning of pipes and tanks.

- Cleans septic tanks, manholes, cesspools and delays pumping.

- Harmless to the ecological environment, certified non-pathogenic micro-organisms.

- Acts quickly.

- Removes bad odors by preventing the formation of H2S.

- Does not contain caustic soda.

- Without attack on the supports - Non-flammable.

- More than 90% biodegradable surfactants.

Applications:

BIOZYME provides an active bacterial flora which digests organic deposits (fats, fatty substances, proteins, starch and cellulose) contained in grease traps, septic tanks, kitchen and sanitary pipes.

Manual :

- To ensure the good effectiveness of BIOZYME, it is preferable to dilute the product in a small quantity of lukewarm water at 30 - 40°C maximum.

- Leave for 15 to 30 minutes, or even 1 hour, while the bacteria reactivate.

- Then pour this solution into the area to be treated.

GREASE PATS:

- Before treatment, seeding of the system should be done every day for a week at a rate of 40 to 80 g per day.

- Then the system must be treated:

A - Depending on the number of meals:

- From 0 to 50 meals/day: 40 to 60 g/week.

- From 50 to 100 meals/day: 60 to 80 g/week.

- From 100 to 300 meals/day: 80 to 200 g/week.

- From 300 to 500 meals/day: 200 to 320 g/week.

- From 500 to 1000 meals/day: 320 to 480 g/week.

- More than 1000 meals/day: 500 g minimum/week.

B - Depending on the volume of the tank:

- 1500 L: 40-80 g/week.

- 3000 L: 80-200 g/week.

- 5000 L: 200-320 g/week.

- 7500 L: 320-480 g/week.

- Greater than 10,000 L: 500 g minimum/week.

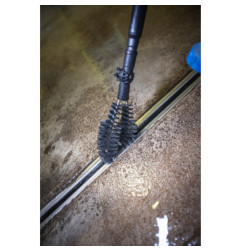

PIPELINES:

In the case of pipe treatment, to prevent clogging, blockage or bad odors, treat with 50 to 100 g of BIOZYME per week.

SEPTIC :

For a septic tank of 1 m3, ensure start-up by adding 100 g to the toilet bowl the first week or directly to the tank.

Routine maintenance, 50 g every 15 days in the toilet bowl and run the water.

Conditioning :

5 kg bucket.

Data sheet

- Signal word

- As of Q4 2023, no signal word is listed for this item when last checked. Please check the latest update of the technical data sheet issued by the manufacturer.

- Hazard statements

- As of Q4 2023, no hazard statements are listed for this item when last checked. Please check the latest update of the technical data sheet issued by the manufacturer.

- Hazard pictogram

Specific References

- EAN13

- 9145385992920

Quelles sont les déclinaisons et prix pour Biozyme - Effervescent biological activator - Zep Industries ?

| Variante | Packaging | Prix HT | Prix TTC | Prix dès 3 pièces (-3%) (TTC) | Prix dès 5 pièces (-6%) (TTC) | Prix dès 12 pièces (-10%) (TTC) | Réference | EAN-13 | Stock* disponible |

|---|---|---|---|---|---|---|---|---|---|

| Biozyme - Effervescent biological activator | 5 kg | €232.10 | €278.52 | €270.17 | €261.81 | €250.67 | ZEP 8550.5 | 9145385992920 | Arrivage |