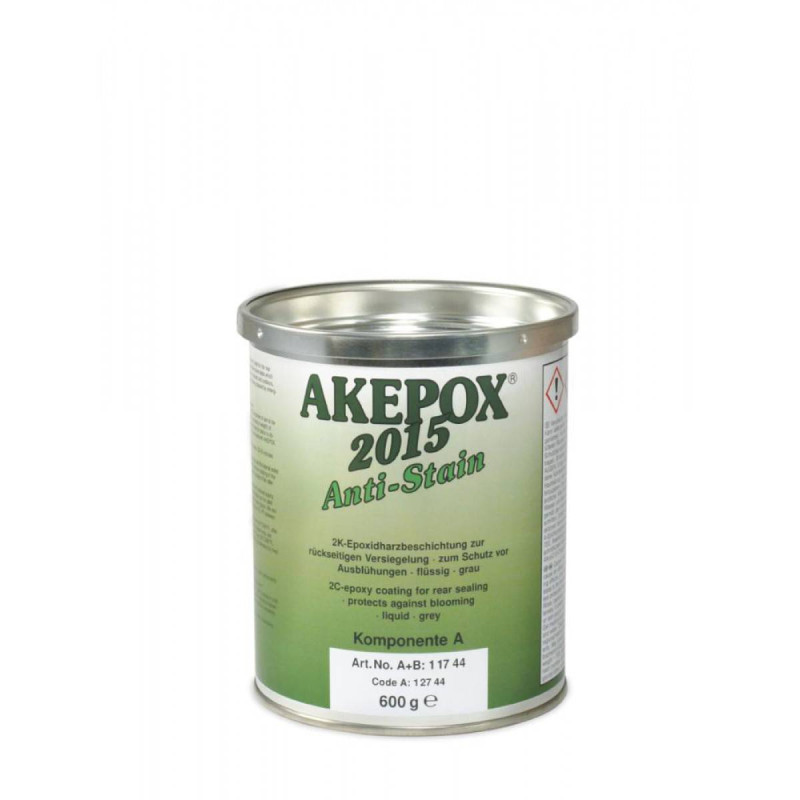

Akepox 2015 Anti-Stain - Liquid epoxy coating - Akemi

Liquid 2-component epoxy coating with filler material to be applied in thin layers to allow high profitability.

Volume discounts

| Quantity | You Save | Unit price |

|---|---|---|

| 6 | 7 % | €77.34 |

AKE 11744

4004208127442

Akepox 2015 Anti-Stain - Liquid epoxy coating - Akemi

Liquid 2-component epoxy coating with filler material to be applied in thin layers to allow high profitability.

For sealing the rear and side faces of natural and artificial stone slabs to prevent traces of rising water and salts.

Prevents or reduces the formation of rust spots.

The sand applied on Akepox 2015 serves as a primary adhesion layer for mortar.

Features :

- Mixing ratio 2:1

- Without solvents

- Very good resistance to alkalis (especially cement-based mortars)

- Weather resistant

- Easy dosing and mixing with simple instructions (see instructions)

- Ease of implementation; does not run on the side surfaces

- Fast and economical processing, thin layer application by roller

- Hardening without shrinkage

- Very good weather resistance

- Very good alkali stability

- Good adhesion on slightly damp stone

- The product does not tend to crystallize, does not hinder storage problems and ensures good processing safety.

Use :

A. Pail Product:

- Remove lid from buckets and stir each component separately before use.

- Attach the perforated lid with the dosing pump to the buckets. Operate the pump until the material arrives.

- In the cup, dose two parts of component A, then dose one part of component B, using the pump, and mix everything until you obtain a homogeneous shade.

- Continue with point 4 of the boxed product.

B. Boxed Product:

- Remove the lid from the boxes and shake each component separately before use.

- Introduce all of component B into component A and then mix until a homogeneous shade is obtained.

- To better empty the box, it is possible to equip it with a spout.

- The mixture can be used for approx. 20 to 30 minutes (at 20°C).

- Spread the mixture on the back side of the dry stone and on the side surfaces, using a short-haired roller.

Cover the side surfaces up to 2/3 of the surface; angle of incidence of the roller approx. 45°. - Consumption approx. 150 to 200 g/m², depending on the roughness and the absorption capacity of the stone.

- Sprinkle the resinated plates completely with sand (granulation of the sand 0.6 to 1.2 mm).

Sanded plates can be stacked on top of each other during curing to reduce clutter.

Place a release film (eg PR or PP) between the treated plates.

Sand consumption approx. 800 to 1000 g per m². - After 6 to 8 hours (at 20°C), the surfaces are dry; after 16 to 20 hours (at 20°C), they can be loaded or ready to be laid.

Maximum strength after 7 days (at 20°C). - Tools can be cleaned with AKEMI thinner.

- Heat accelerates, cold slows hardening.

- Stored in a cool place, the product can be worked for at least 1 year.

Conditioning :

900g and 15kg

AKE 11744

Data sheet

- Signal word

- DANGER

WARNING - Hazard statements

- H314 – Causes severe skin burns and eye damage.

H315 – Causes skin irritation.

H317 – May cause an allergic skin reaction.

H319 – Causes serious eye irritation.

H332 – Harmful if inhaled.

H341 – Suspected of causing genetic defects.

H361 – Suspected of damaging fertility or the unborn child.

H411 – Toxic to aquatic life with long lasting effects. - Hazard pictogram

GHS05 - Corrosive

GHS05 - Corrosive

GHS07 - Harmful

GHS07 - Harmful

GHS08 - Health hazard

GHS08 - Health hazard

GHS09 - Environmental hazard

GHS09 - Environmental hazard

Specific References

- EAN13

- 4004208127442

Quelles sont les déclinaisons et prix pour Akepox 2015 Anti-Stain - Liquid epoxy coating - Akemi ?

| Variante | Packaging | Prix HT | Prix TTC | Prix dès 6 pièces (-7%) (TTC) | Réference | EAN-13 |

|---|---|---|---|---|---|---|

| Akepox 2015 Anti-Stain - Liquid epoxy coating | 900 g | €69.30 | €83.16 | €77.34 | AKE 11744 | 4004208127442 |

| Akepox 2015 Anti-Stain - Liquid epoxy coating | 15 kg | €802.62 | €963.14 | €895.72 | AKE 11717 | 4004208117184 |