- Home

- Sika

- Floors - Sika

- Exterior view - Sika

- Concrete & Repair - Sika

- Waterproofing & Protection - Sika

- Gluing & grouting - Sika

- Related Products & Materials

- Sika Industry

- Elastic adhesives and sealant - Sika

- Structural adhesives - Sika

- Hybrid epoxy-polyurethane - Sika

- Adhesives for sandwich panels - Sika

- Trailer screeds - Sika

- Hotmelt - Sika

- Contact adhesive and PU coatings - Sika

- Cyanoacrylate rapid adhesives - Sika

- Butyl rubber - Sika

- Automotive aftermarket products - Sika

- Preparation product - Sika

- Navy - Sika

- Floors - Sika

- Soudal

- Lithofin

- Akemi

- Glues & Sealants - Akemi

- Cleaning - Akemi

- Maintenance - Akemi

- Protection - Akemi

- Silicone & polymer - Akemi

- Maintenance products - Akemi

- Automotive range - Akemi

- Mastics, hardeners - Akemi

- Resins, fabrics - Akemi

- 2 c - acrylic products - Akemi

- Anti-corrosion and anti-gravel - Akemi

- Colour Sprays, Primers - Akemi

- Technical sprays and special-purpose products - Akemi

- Lubricants and greases - Akemi

- The plastic elements repair system - Akemi

- Repairs of tires - Akemi

- Protection and repair materials for exhaust pipes - Akemi

- Rust protection - Akemi

- Radiator protection and repair - Akemi

- Glueing, sealing - Akemi

- Cleaning, polishing - Akemi

- Skin protection - Akemi

- Thinners - Akemi

- Afin

- Catalfer

- Owatrol

- Rectavit

- Guard Industrie

- Fila

- Tec7

- HG

- Natural stone - HG

- Tiles - HG

- Terracotta - HG

- Parquet & wood - HG

- Parquet - HG

- Floor - HG

- Cork - HG

- Laminate - HG

- Soils plastic - HG

- Carpet & flooring - HG

- Brico - HG

- Garden - HG

- Interior - HG

- Kitchen - HG

- Health - HG

- Toilet - HG

- Pipes - HG

- Air Care - HG

- Mold - HG

- Textile - HG

- Furniture - HG

- Devices - HG

- Car, boat & trailer - HG

- Gold, silver & copper - HG

- Leather - HG

- Sponges etc. - HG

- Insecticides - HG

- Eco

- Disinfection - HG

- Blue Wonder

- P.T.B. Compaktuna

- Aquaplan

- Moeller Stone Care

- Eres-Sapoli

- Nettoyage d'Antan Eres-Sapoli

- Entretien des Sols - Eres-Sapoli

- Entretien et Soin du Bois Eres-Sapoli

- Cheminée Poêles BBQ Eres Sapoli

- Nettoyants Métaux - Eres-Sapoli

- Bain et Sanitaire - Eres-Sapoli

- Cuisine ménage - Eres-Sapoli

- Linge Détachant - Eres-Sapoli

- Désinfecter Hygiène - Eres-Sapoli

- Eponges & Lavettes - Eres-Sapoli

- Soin du cuir -Eres-Sapoli

- Produits Divers - Eres-Sapoli

- Entretien Voitures - Eres-Sapoli

- WD-40

- Zep Industries

- Industry - Zep Industries

- Institution - Zep Industries

- Food and beverages - Zep Industries

- Water treatment - Zep Industries

- Transport and automotive - Zep Industries

- Building and construction - Zep Industries

- Professional cleaning and maintenance - Zep Industries

- Disinfectants & hygienic cleaners - Zep Industries

- Multipurpose detergents - Zep Industries

- Absorbents - Zep Industries

- Paints & coatings - Zep Industries

- Other products - Zep Industries

- Hand cleaners - Zep Industries

- Air conditioning - Zep Industries

- Air fresheners - Zep Industries

- Pipeline maintenance - Zep Industries

- Insecticides & herbicides - Zep Industries

- Paper and safety equipment - Zep Industries

- Industry - Zep Industries

- Pollet

- Other brands

- Riem

- OXI - Paints

- Illbruck

- Berdy

- IKO Pro

- Linitop

- Rubson

- Moisture absorbers - Rubson

- Home and garden - Rubson foundations

- External walls - Rubson

- Rising damp - Rubson

- Cellar Assortment - Rubson

- Roofing and gutters - Rubson

- Sealing of fittings - Rubson

- Interior walls - Rubson

- Floors indoor and outdoor - Rubson

- Sealing mastics - Rubson

- Preparation of surfaces - Rubson

- Sealants - Rubson

- Foam insulation - Rubson

- Foam construction - Rubson

- Accessories mastics and foam insulation - Rubson

- Wood lover

- Pattex

- tangit

- Loctite

- Techniseal

- Parexlanko

- Bauma Stone

- Vosschemie Soloplast

- Epoxy - Vosschemie Soloplast

- Polyester - Vosschemie Soloplast

- Polyurethane PU - Vosschemie Soloplast

- Silicone rubber - Vosschemie Soloplast

- Acrylic - Vosschemie Soloplast

- Putty - Vosschemie Soloplast

- Excipient - Vosschemie Soloplast

- Polyester fiber - Vosschemie Soloplast

- Application Tool - Vosschemie Soloplast

- System Kit - Vosschemie Soloplast

- Treatment and products

- Vikan

- Agri-food processing - Vikan

- Dairy products - Vikan

- Bakery & Pastry - Vikan

- Meat processing - Vikan

- Confectionery manufacturing - Vikan

- Ready-to-eat fresh food processing - Vikan

- Manufacturing of dry “ready-to-eat” products - Vikan

- Large food distribution - Vikan

- Customer restaurant - Vikan

- Bakery - Vikan

- Catering area - Vikan

- Fishmonger - Vikan

- Butchery - Vikan

- Warehouse, Parking and Vehicle Wash - Vikan

- Takeaway - Vikan

- Hardware store

- Mortar - Glue - Joint

- Pedestals

- Wall and floor profiles

- Couvercle, regard, Trappe et Porte pour les sols, murs et toits

- doormat and frame

- Floor accessories

- Water Management

- Sécurité - Handicap - PMR

- HDPE turf stabilizer

- HDPE gravel stabilizer

- Interior floor

- Exterior floor

- Various soils

- Wall cladding

- CUSTOM stone

- Home improvement

- Landscaping

- Tools and construction equipment

- Axes

- Croisillons et Systèmes de pose autonivelants

- Caulking gun

- Sprayer

- Application material

- Tile handling and suction lifter

- Drill and Drill

- Earthmoving equipment

- Foundation materials

- Shovels and rakes

- Hammers and sledgehammers

- Matériels de pose

- Cutting tools

- Woodworking knives

- Crowbar

- Diamond discs

- Tools for completion

- Tools for the rejointoyage

- Sanding and polishing

- Measurement tools

- Power Tools

- Machine to knead

- Malaxeurs

- Renovation milling machine

- Concrete grinder

- Polishers

- Plaquist Sander

- Power trowel

- Circular saw

- Radial saw

- Roll Groover

- Cutter diamond

- Demolition Hammer

- Core drill diamond

- Drill

- Accessories

- Radial and circular saw

- Finisher

- Zamboni

- On table saws

- Couronnes - Diam Industries

- Floor saws

- Angle grinding machine

- Adhesive strips

- Cutter knives

- Buckets and tubs

- Clamps

- mason's ropes

- Hand saws

- Wood chisels

- Ventilation grilles - RENSON

- 'Free' sample

- Online plan

- Promotions

- Used equipment

- Gondore - Rayonnage - Etagère d'occasion

- Sand - gravel - cement

- discontinued

- Sika - Non-catalogue products

- Soudal - Non-catalogue products

- Lithofin - Non-catalogue products

- Akemi - Non-catalogue products

- Guard Industrie - Non-catalogue products

- Owatrol - Products out of stock

- Rectavit - Non-catalogue products

- Fila - Non-catalogue products

- HG - Non-catalogue products

- Tec7 - Non-catalogue products

- PTB Compaktuna - Non-catalogue products

- Aquaplan - Non-catalogue products

- Parexlanko - Non-catalogue products

- HMK - Non-catalogue products

- Berdy - Non-catalogue products

- Other Brands - Non-catalog products

- Other Products - Non-catalog products

- Pierre - Non-catalogue products

- Zep Industries - Non-catalogue products

- Solar photovoltaic

- Pro and loyalty card

- Cyclist & Cyclo Sponsoring

- Algimouss

- Sika

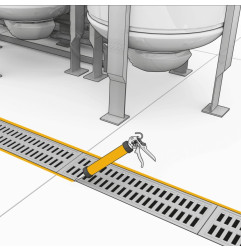

SikaFlex Tank N - Chemical Resistant Elastic Mastic - Sika

Sikaflex Tank N is a one-component, elastic, moisture-curing sealant.

Volume discounts

| Quantity | You Save | Unit price |

|---|---|---|

| 10 | 5 % | €22.64 |

| 20 | 10 % | €21.45 |

SikaFlex Tank N - Chemical Resistant Elastic Mastic - Sika

Sikaflex Tank N is a single-component sealant , elastic, polymerizing under the action of humidity in the air.

Features

- Monocomponent, ready to use.

- Easy to apply

- High chemical resistance.

- High mechanical resistance.

- ±25% movement capability.

- Steady.

- Good processing properties.

- High tear resistance.

Application areas

Sikaflex Tank N should only be used by professional applicators.

Sikaflex Tank N has been designed for use in environments used for the storage, filling and handling of water polluting liquids such as: floor joints in gas stations, joints in handling areas, tanks storage and containment, and floor expansion and connection joints in car parks.

Application

- The support must be clean and dry, sound, homogeneous, free of oil, grease, dust and friable or loose particles.

- Cement laitance must be removed.

- Sanding the surface of non-porous substrates with a very fine abrasive pad can improve the adhesion of Sikaflex Tank N.

The Sikaflex Tank N joint system is certified for application between uncoated precast concrete elements.

Sikaflex Tank N has technical approval for use in areas for the storage/filling/handling of water-polluting liquids, or concrete grades ≥C35/C45 and ≤C50/60 (EN 206-1), or between cast-in-situ concrete elements classified according to DIN 1045 as "FD" (liquid-tight concrete) or "FDE" (concrete tested against liquid penetration).

Non-porous substrates:

- Aluminum, anodized aluminum, stainless steel, galvanized steel, thermo lacquered powder-based metals or vitrified tiles must be cleaned and then pre-treated with Sika Aktivator-205 using a cloth own.

Maintain an evaporation time of at least 15 minutes (maximum 6 hours) before applying the mastic. - Other metal surfaces such as copper, brass and titanium zinc should also be cleaned and then pre-treated with Sika Aktivator-205 using a clean cloth.

After the necessary evaporation time, apply a coat of Sika Primer-3 N using a brush.

Maintain an evaporation time of at least 30 minutes (maximum 8 hours) before applying the mastic. - The PVC must be cleaned and then pre-treated with Sika Primer-215 using a brush.

Before applying the mastic, let the primer dry for at least 30 minutes (maximum 8 hours).

Porous substrates:

- Concrete, aerated concrete, cementitious plasters, mortars and bricks must first be primed with Sika Primer-215 for applications according to ETA-09/0272, or Sika Primer-3 N applied with a brush or clean roller.

Allow a minimum drying time of 30 minutes (max. 8 hours) before applying the mastic.

Consumption

| Joint length (m) per 600 ml bag | Joint width (mm) | Joint depth (mm) |

|---|---|---|

| 6 | 10 | 10 |

| 3.3 | 15 | 12 |

| 1.9 | 20 | 16 |

| 1.2 | 25 | 20 |

| 0.8 | 30 | 24 |

Conditioning

600ml bag.

Data sheet

- Signal word

- DANGER

- Hazard statements

- H317 – May cause an allergic skin reaction.

H332 – Harmful if inhaled. - Hazard pictogram

-

GHS08 - Health hazard

GHS08 - Health hazard

Specific References

- EAN13

- 7612894633962

Download

You might also like

Customers who bought this product also bought:

Sikaflex Tank N is a one-component, elastic, moisture-curing sealant.